|

|

#71

|

||||

|

||||

|

Quote:

Seals on the mains? yer shiddin me! Only ever seen that once before & it was on an old TS125 engine I bought & was told had been re-cond by a dealership which was a blatent lie & found all sorts of sins including no crank seals (maybe they thought the bearing seals were enough) & internal type circlips instead of plain wire ones (must have been easy to fit, silly factories for not using them, bleeugh!) |

|

#72

|

||||

|

||||

|

Quote:

Peace of mind. In regards to sealed mains. It looks like every GG out of the factory from 2009 onwards has been using them. Peace of mind. In regards to sealed mains. It looks like every GG out of the factory from 2009 onwards has been using them.

|

|

#73

|

||||

|

||||

|

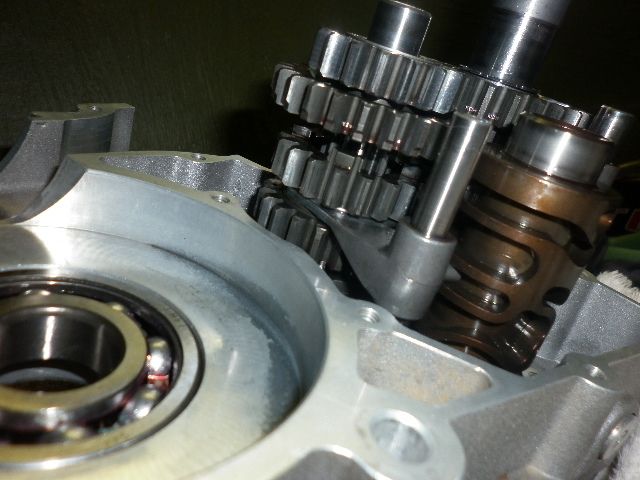

Today I was pretty busy with other things and the bike wasn't a priority, but I managed to set a bit of time aside to get my head around the gearbox. All slid back together as it should and I can put it through the gears. These photos are of it sitting in neutral.

|

|

#74

|

||||

|

||||

|

The reason C4 clearance bearings are used is to allow a tighter press fit, or to allow a wider tolerance for the press fit than may end up tighter. Jake, from what you describe about assembly your cases seem normal. C3s would be fine in this case. If R&R was tough I'd say C4. Not all bearings are readily available in C4.

GasGas has had problems in the past with press fits. Many '99s were too tight and crank bearings failed often. '00 had a pretty tight case fit, but a very loose crank fit that caused the crank to spin and the journals to wear. I had a '00 250 and '01 125 like this. They then went to the two part roller bearing(a LOT more running clearance than any 6206 radial ball) and all seemed well as a rule. Now we get this mess. I like getting paid for R&D, not paying for it. |

|

#75

|

||||

|

||||

|

More of your knowledge being shared around. Very appreciated Glenn

Another quick question. The crank shaft o-ring. Where does this go? I know it sits in with the seal and bushing, but it doesn't seem like there is a groove or anywhere to specifically locate it. Also, when is the prefered time to install all the seals? Before the cases are back together and crank installed? or slide them over and seat them after? |

|

#76

|

||||

|

||||

|

Jake,

The oring goes on the crank behind the sleeve. It functions to seal the crank/sleeve just like the design of the countershaft. Seals can go in first. Its VERY IMPORTANT to only seat them flush, too deep and they can block the oil holes. There are no stops counterbored in the cases. The primary side seal rides on the sleeve, and that(with oring) will be installed with all the primary hardware. Just grease them up good and make sure everything is clean and free of knicks, etc. from all the handling. If a crank fit is tight in a main bearing, I may leave the seals out and warm the case/bearing for an easier install. I did a motor like this once but I suspect you will have no problems. |

|

#77

|

||||

|

||||

|

Thanks again. I think I'll hold off and put the seals in at the end just incase if I have any struggles along the way. Already have the trans in the primary side anyway. Taking special note only to install seals flush.

|

|

#78

|

||||

|

||||

|

Jake,

You can get dry ice down there can't you? Freeze the crank and it will just drop in a warm bearing. Sent from my iPad using Tapatalk HD |

|

#79

|

||||

|

||||

|

Should be able to get it from a party supply store.

|

|

#80

|

|||

|

|||

|

Quote:

Loving this thread  Ollie |

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| First Top-End Rebuild on a 2007 EC250 | speedy08 | Enduro Engine - 2 stroke | 9 | 06-22-2011 09:16 PM |

| EC250 engine rebuild? | robszombie | Enduro Engine - 2 stroke | 3 | 12-07-2009 11:38 AM |