|

|

|||||||

| Enduro Engine - 2 stroke Cylinder, Piston, Tranny, Bearings, Clutch, Pipes & Silencers, etc. |

|

|

|

Thread Tools | Display Modes |

|

#1

|

||||

|

||||

|

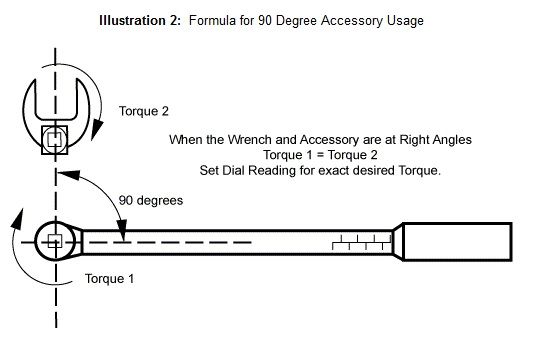

Here's a trick one can use to torque nuts which you can't redily access; applying the torque through an arm 90 degrees to the torque wrench is equivalent. So in the case of the recessed forward cylinder nuts in my ec300 I engage the nuts with the closed end of a 13mm box end wrench, and then I apply the torque (25NM I think) to the open end of the box end wrench. The torque wrench and box end wrench are at 90 degrees to one another. And the connection between the wrenches is conveniently easy as the 13mm wrench can be driven my the 1/2" output of my torque wrench (12.7mm).

The trick to realize is that torque is a function of the length of the arm, but that when the wrench is maintained at 90 degees to the torque wrench the arm length has not changed and so the torque is the same. Have fun wrenching. Dale. |

|

#2

|

||||

|

||||

|

Cool tip, thanks!

__________________

2007 (or 2008) EC300 (with 2011 Plastics Mod) 2011 EC300 (rock ready!) |

|

#3

|

|||

|

|||

|

That's interesting information. Would it be possible to complement this with some cool pics ?

__________________

Vindicator '11 EC 300R |

|

#4

|

||||

|

||||

Basically, if changing the pivot point/axis the torque will need to be adjusted. If keeping everything in line no issues. |

|

#5

|

|||

|

|||

|

Thanks Jakobi. What my mind is fighting to achieve

is what's the proper tool combination to use for this . How to have the torque wrench connected to the 13mm on the nut is what's the proper tool combination to use for this . How to have the torque wrench connected to the 13mm on the nut  ? ?While we are at this torque talk , If I use a socket wrench extension bar with the torque wrench will the actual torque be the same ? The distance of the torque wrench to the nut has an influence on the torque ?

__________________

Vindicator '11 EC 300R |

|

#6

|

|||

|

|||

|

As mentioned a 13mm ring/open end spanner combo works a treat with a 1/2 inch drive torque wrench. The ring end slips onto the cylinder nut and the 1/2' drive fits perfectly into the 13mm open end of the spanner.

Re the extensions, shouldn't make any difference, but I'm no expert and don't know for sure. Hope not cause I use an extension to reach the head bolts...

__________________

Current: 2014 Gas Gas EC300R _____________________________________________ Previous: 2011 Gas Gas EC300 ELC 2004 KTM 300 EXC |

|

#7

|

|||

|

|||

|

Quote:

Sorry but my technical English is not as good as I would like it to be

__________________

Vindicator '11 EC 300R |

|

#8

|

||||

|

||||

|

Like they both said. 13mm fits onto the 1/2" drive.

Both extensions you have listed work fine as they don't change the axis. The same amount of leverage is applied to the pivot from the handle, and the bolt is still the same position as the pivot. The time this would change though, would be if you were using the wobble attachment function on the extension, then the difference in offset depending on the angle would have an effect on the amount of leverage applied. |

|

#9

|

|||

|

|||

|

Quote:

__________________

Vindicator '11 EC 300R |

|

#10

|

|||

|

|||

|

I welded a old crappy ring spanner which I cit in half to a socket , kept the spanner short so hopfy it does not meds the tourqe setting up to much

Works spot on

__________________

03 ec300 honda cr500 94 |

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Cylinder Base nuts | Marki | Enduro Engine - 2 stroke | 20 | 03-12-2012 10:04 PM |

| Setting new cylinder studs - torque | motogroove | Enduro Engine - 2 stroke | 3 | 07-20-2011 02:04 AM |

| Torque cylinder head EC 300 2009 | Klausen | Enduro Engine - 2 stroke | 9 | 10-03-2010 10:49 AM |

| torquing cylinder base nuts.... | stainlesscycle | Enduro Engine - 2 stroke | 17 | 03-08-2010 06:42 AM |

| Cylinder Bolt Torque? | eff | Enduro Engine - 2 stroke | 12 | 03-30-2008 08:44 AM |